High temperature process filters in Houston are industrial filtration systems designed to operate safely under extreme heat conditions in oil & gas applications. These filters remove solid contaminants from hot process fluids without compromising flow rate, pressure stability, or system safety.

From refineries to offshore platforms, industries worldwide depend on high-temperature filtration for consistent performance and equipment protection. In Houston, where oil & gas processing is continuous and high-load, automatic industrial process filters are critical for maintaining safe and efficient operations.

High temperature process filters help Houston oil & gas facilities maintain clean fluid flow, protect equipment from thermal damage, and ensure uninterrupted production using automatic industrial systems.

What Are High Temperature Industrial Process Filters?

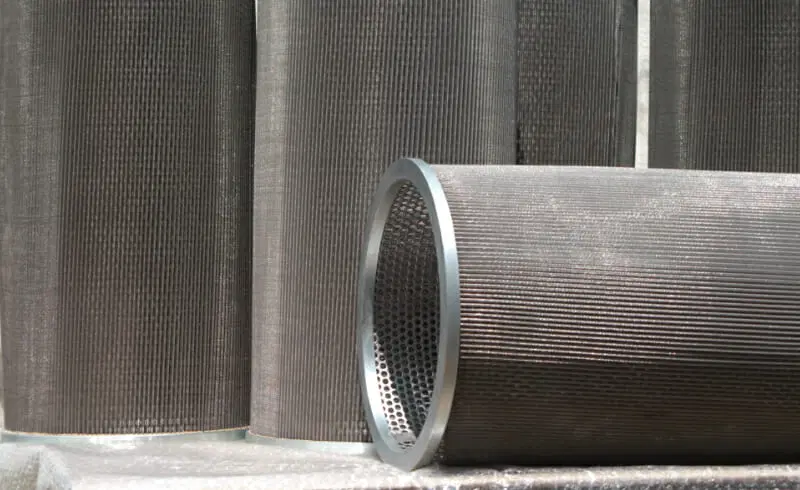

High temperature industrial process filters are engineered filtration units built to handle extreme heat while removing solid contaminants from oil, gas, and chemical process fluids.

- Designed for continuous operation at elevated temperatures

- Built using heat-resistant metals and reinforced housings

- Used in refineries, petrochemical plants, and thermal processing units

- Maintain filtration efficiency without thermal deformation

- Support high-pressure and high-flow industrial systems

What Temperature Ranges Do These Filters Typically Handle?

Depending on the material and design, high temperature process filters can operate safely in environments ranging from moderately hot fluids to extremely high-temperature process lines used in refining and chemical reactions.

Why Are High Temperature Process Filters Essential in Houston Oil & Gas Facilities?

Houston oil & gas facilities rely on high temperature process filters to safely manage hot hydrocarbons, fuels, and process liquids without clogging or system failure.

- Protect pumps, compressors, and control valves from solid contamination

- Prevent heat-related structural damage inside filtration systems

- Ensure stable flow in high-temperature refining processes

- Reduce unplanned shutdowns caused by overheating and fouling

- Support compliance with industrial safety protocols

Which Houston Oil & Gas Operations Use These Filters?

- Crude oil distillation units

- Hydrocarbon cracking systems

- Hot lube oil circulation lines

- Gas dehydration and treatment plants

- Thermal recovery and steam injection systems

What Are Automatic Industrial Process Filters for Oil and Gas?

Automatic industrial process filters for oil and gas are self-cleaning filtration systems that remove contaminants continuously without manual intervention.

- Use automatic backflushing or scraping mechanisms

- Maintain uninterrupted process flow during cleaning

- Reduce maintenance labor and manual filter handling

- Provide consistent filtration under high temperature and pressure

- Improve plant uptime and operational reliability

How Do Automatic Filters Improve Plant Efficiency?

Automatic process filters minimize human intervention, prevent sudden pressure drops, and maintain continuous protection of critical equipment in 24/7 oil & gas operations.

How Do High Temperature Filters Improve Equipment Protection?

High temperature filters protect critical oil & gas equipment by preventing hot solid particles from eroding internal components and causing thermal stress failures.

- Prevent abrasive wear in pumps and turbines

- Protect heat exchangers from clogging

- Reduce corrosion caused by contaminated hot fluids

- Maintain smooth valve operation under extreme heat

- Extend equipment service life

What Happens When High-Temperature Filtration Is Inadequate?

- Increased maintenance frequency

- Higher risk of thermal deformation

- Unstable pressure conditions

- Reduced product quality

- Increased risk of safety incidents

How Does SG Industrial Inc. Support High Temperature Filtration in Houston?

SG Industrial Inc. supplies high temperature industrial process filters and automatic filtration systems for oil & gas facilities in Houston and across the USA.

- Provides filters suitable for extreme thermal environments

- Supports automatic and manual high-temperature filtration systems

- Offers custom-engineered filtration solutions for hot process fluids

- Delivers replacement filtration elements for continuous operations

- Supports refinery, petrochemical, and offshore filtration needs

Typical Applications Supported

- High-temperature fuel filtration

- Thermal oil circulation systems

- Hot hydrocarbon processing

- Steam-assisted oil recovery systems

- Refinery process transfer lines

How Do High Temperature Process Filters Serve Global Energy & Industrial Regions?

High temperature industrial process filters are critical across global energy hubs and thermal processing zones.

- Widely used in Houston (USA), Alberta (Canada), the North Sea (UK), the Persian Gulf, Singapore, and Southeast Asia

- Support offshore platforms, LNG terminals, and refinery clusters

- Enable safe high-heat processing in export-driven energy regions

- Improve reliability in power generation and chemical manufacturing zones

Summary

High temperature process filters are essential for safe and efficient oil & gas operations in Houston’s demanding thermal environments. Automatic industrial filtration systems help protect equipment, reduce downtime, and maintain uninterrupted flow. SG Industrial Inc. supports these applications with high-performance filtration solutions built for extreme heat and pressure.

Looking for reliable high temperature process filtration for your oil & gas system? SG Industrial Inc. can help you select the right solution.

Frequently Asked Questions

They are built using heat-resistant materials and reinforced structures to prevent thermal distortion at elevated temperatures.

Because they reduce manual cleaning, prevent shutdowns, and maintain uninterrupted filtration in continuous operations.

Yes, high-temperature industrial filters are engineered for both extreme heat and pressure conditions.

Maintenance intervals depend on contamination levels, but they are significantly longer than manual filter systems.

Yes, when designed for marine-grade corrosion resistance and extreme thermal environments.