High-Performance Filtration for Liquids and Gases

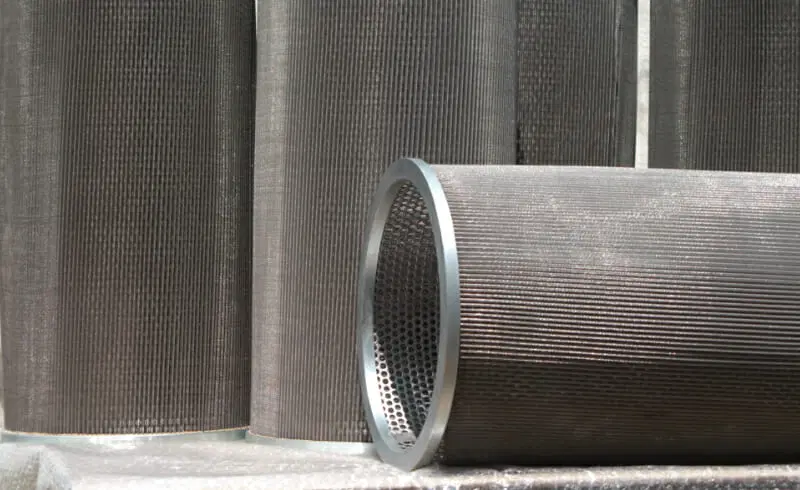

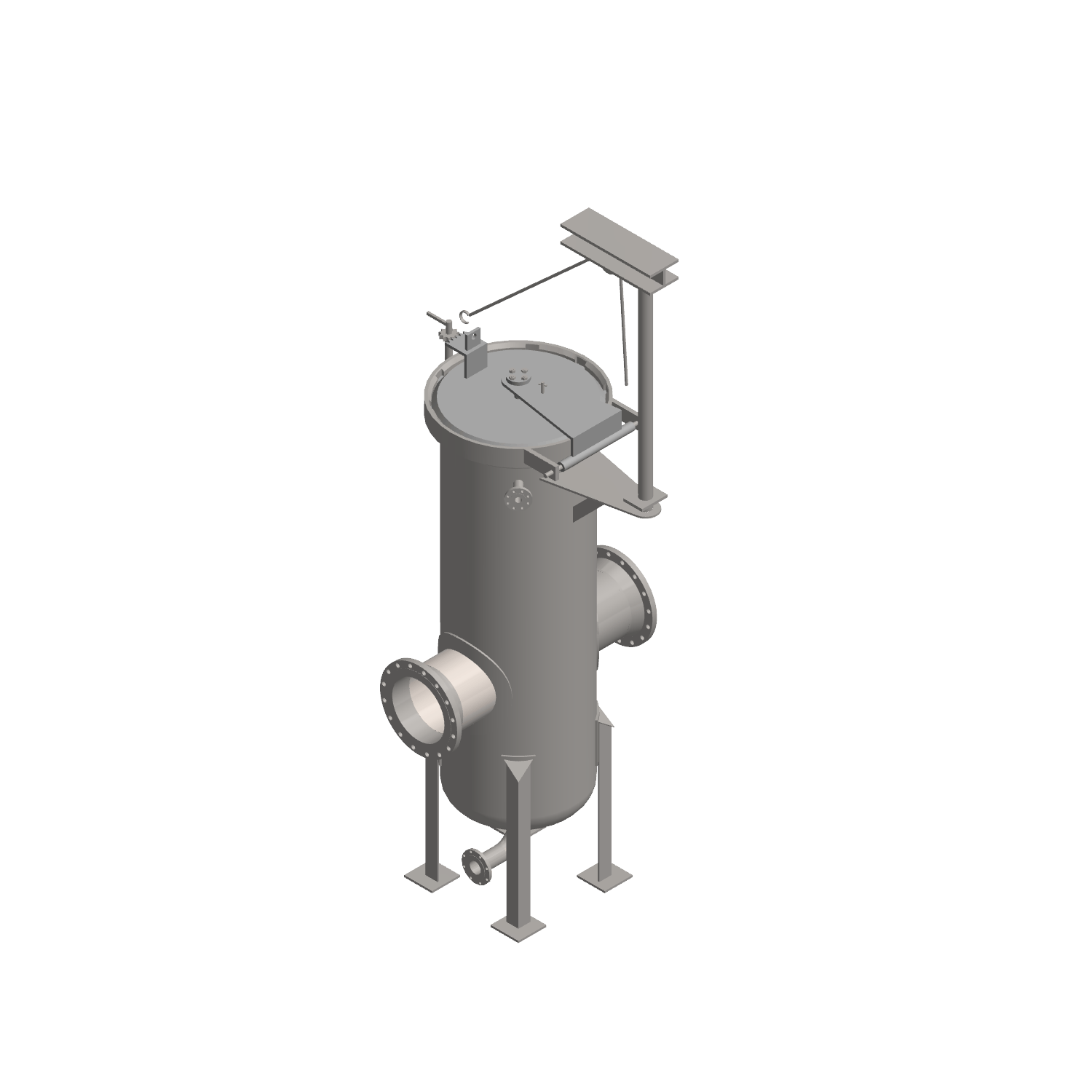

SG Industrial Inc. supplies a comprehensive range of Cartridge-Type Process Filters—designed and manufactured by Sungov Engineering—to provide effective, high-capacity filtration for both liquids and gases. Built for demanding process conditions, these filters ensure contaminant removal, process reliability, and protection of critical downstream equipment.

Key Benefits:

- Versatile Filtration Solutions

• Suitable for a wide range of liquid and gas service

• Single or multi-cartridge configurations for varied flow rates

• Compatible with pleated, depth, and sintered cartridges

- Robust Construction

• Fully fabricated housings in carbon steel, stainless steel, and specialty alloys

• Pressure ratings available up to Class 1500

• Housings available with or without ASME “U” Stamp to suit project specifications

- Large Capacity Options

• Housing diameters up to 12 feet for high-volume service

• Quick-opening closures available for reduced maintenance time

• Drain and vent connections standard; differential pressure ports optional

Technical Overview:

| Design Pressure | Up to Class 1500 |

|---|---|

| Temperature Range | -20°F to 750°F |

| Standard Sizes | Up to 12 feet |

| End Connections | Flanged, or butt-welded |

| Construction Materials | Carbon steel, stainless steel, duplex, or special alloys |

| ASME Certification | Optional “U” Stamp available |

| Quick Opening Closures | Optional for rapid cartridge changeout |

Why Choose SG Industrial Inc. Cartridge-Type Process Filters?

Engineered for Demanding Applications

Each unit is built to provide consistent, high-efficiency filtration under a variety of flow conditions and process requirements.

Customized to Your Needs

Options for ASME-stamped or non-stamped designs, quick-opening closures, and customized cartridge configurations—tailored to meet your process needs.

Industry-Ready

Designed to comply with ASME codes and other industry standards, ensuring dependable performance in oil & gas, chemical, and general industrial sectors.

Typical Applications:

• Process water filtration

• Crude oil and hydrocarbon service

• Chemical process lines

• Power generation systems

• Pump and compressor protection

Frequently Asked Questions:

A high temperature process filter Houston-grade is built to withstand elevated temperatures (often 400 °F or more), using materials (e.g. stainless steel, Inconel) and gaskets rated for thermal stability to ensure reliable filtration in extreme heat environments.

Yes — our process filter housings are designed, fabricated, and inspected in compliance with ASME Boiler & Pressure Vessel Code (BPVC) to ensure safety, pressure integrity, and regulatory compliance.

Absolutely — we provide turn-key automatic process filter systems across the USA, including PLC control, backwash or self-cleaning modes, and full integration with existing plant operations.

Yes — we manage full process filter installations throughout Texas, including site survey, civil support, piping hookup, testing, and commissioning.

Automatic systems reduce downtime by self-cleaning or backwashing, maintain lower pressure drops consistently, minimize manual intervention, and protect downstream equipment from fouling.

-

Oil & Gas

-

Petrochemical & Chemical

-

Power Generation

-

Environmental

-

Utilities

Filter Separators

Duplex Basket Filters & Strainers

Quick Opening Closures

Self-Cleaning Strainers & Filters

Custom Vessels & Exchangers

T & Conical Strainers